Mounting

the suspension:

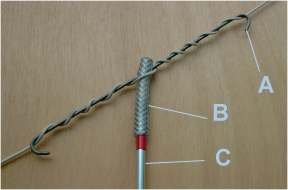

The tube B is drilled at

45° askew Ø 2mm.

The rod A is inserted in

the hole, and bended at each end.

The top end of the tube C

is slipped forward 15mm in the plastic tube. It must go

by force. If it was not holding properly, slightly increase

its diameter. Usually, the aluminum tubes are 6.2mm, which

goes well.

This end is used for the rotation

of the craddle, so there is no other clamping. I have tested

15mm fitted pipes and they hold up to 11kg, which is enough

safe for lifting 500g or less.

Test the

length of the nesting and the force necessary to extract

it for each case of stem and tube. Normally,

to extract the stem, it must be pushed on the fitted

end of the tube and not pull it on the free end.

The red tape is there to verify

that the pipe and the tube are correctly fitted.

After each use, unfit the

stem and the tube to avoid that the tube takes the shape of

the stem and loose its tightening efficiency. |

|

Mounting the cradle:

The tube C is drilled Ø

3 at its lower end.

At each end, the shape D

is notched and drilled Ø3mm. A craftiness is to drill

first Ø2.5mm, and to tap Ø3 one side, then

to drill Ø3mm the other side. Thus, the bolt Ø3

will be screwed on the tapped side, and locked. On the other

side, a wing-nut will let tighten. Put a drop of glue to

avoid to lost the nut..

The step part E is drilled

with two holes set perpendiculary.

The part is cut to save weight.

The holes Ø6.5mm to mount the cameras are determined

for each one. (on the picture, for Olympus epic, stylus,

AF10 mini, andt AF10XB)

|